Coke gas cooling

Description.Proposed process control automation system improves:

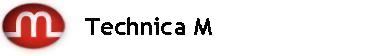

Primary cooling

CokCoke oven outgoing steam and gas products have temperature of 750-800°C and are cooled down to the temperature of 85-90°C by ammonia liquor provided by condensation plant to to gas withdrawal fittings. Then gas comes to primary gas coollers to be cooled to the temperature of 30-35°C. While coke gas cooling the tar and water condensates from it. All condensated products are forwarded for tar and water separation.

Process control automation system implementation provides:

- coke gacoke gas temperature control before and after coollers;

- cooling water temperature control;

- mechanimechanism and process equipment status control;

- level control of condensated products.

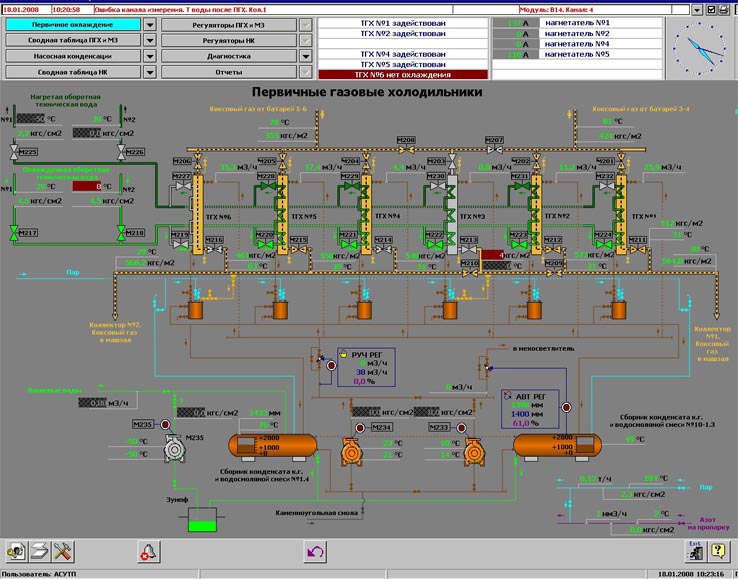

Final cooling

Coke gas temperature after ammonia recovery is about 55-70°C. It is necessary to cool coke gas before benzol recovery. Thus, c. The coke gas final cooling allows to decrease the temperature of gas mixture to 30-35°C.

During coke gas cooling the part of water is condensated and naphthalene is washed out at the same time. Moreover, the more intensive liquor spraying and the lower coke gas temperature the more naphthalene is washed out.

Process control automation system implementation provides:

- coke gacoke gas temperature control before and after coollers;

- cooling water temperature control;

- mechanimechanism and process equipment status control;

- level control of condensated products.