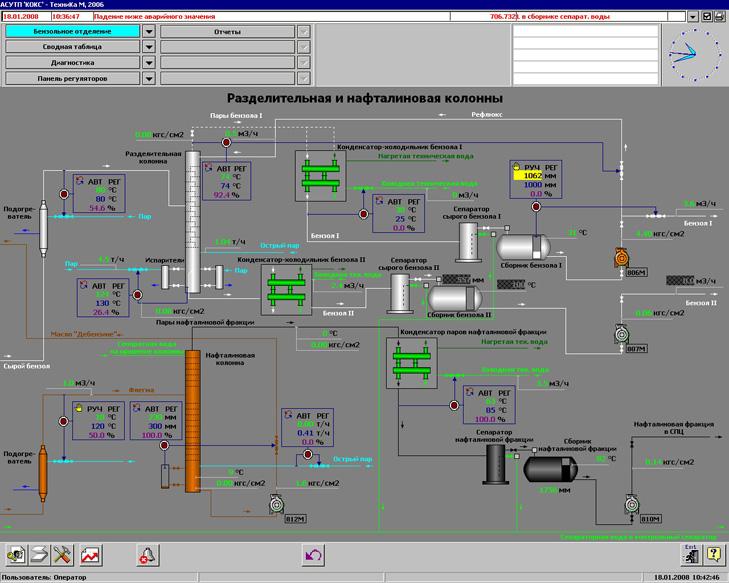

Benzol and naphthalene recovery plant

Main processes:

Description

After ammonia recovery the coke oven gas comes to raw benzol recovery. The recovery is taking place due to contact of the coke oven gas with wash oil in scrubbers, at the same time, benzol plant provides final cooling of coke oven gas. The result coke gas could be transfered to customers, for instance, for coke oven battery heating.

Wash oil enriched with raw benzol is heated to the temperature of 140°C and being purified from raw benzol and cooled, it is returned to srubbers for continuous use.

Along with raw benzol recovery the naphthalene fraction is removed and transfered to naphthalene tower for subsequent purification.

Proposed process control automation system improves:

- distillation tower operation control (raw benzol recovery);

- separation tower operation control (benzol light and heavy fraction recovery);

- final coke gas cooling;

- process equipment control.