Mathematical model of coking process

DescriptionMathematical model of coking process is central part of coke oven automation system. Its main purpose is to calculate optimal setpoints for coking process, send commands to actuators and generate recommendations for battery stuff.

Coking process model uses different input data, such as:

- reference data, specified during design/commissioning – battery geometry, process coefficients, setpoints, etc.;

- laboratory analysis results – blend analysis, heating gas analysis, etc.;

- measurements from portable devices – temperatures in heating verticals, pressures in heating subsystem, etc.;

- fixed position sensor measurements;

- process archive data.

Coking process model calculates:

- figures, setpoints, schedules, etc. -set temperatures, pressures, push/charge schedules, etc.;

- predictable process parameter values;

- setpoints for actuators, calculated on the base of different algorithms;

- battery staff recommendations represented as texts, charts, etc.

The coking model can operate either in automatic or recommendation modes. The automatic mode assumes that battery staff must input necessary manual data, if it is not available in electronic form, the control of actuators setpoints is made automatically. The recommendation mode assumes that model calculates all setpoints the same way as with automatic mode, but they are not sent as commands and submitted for battery staff for evaluation. Battery personel can take decision on their further implementation.

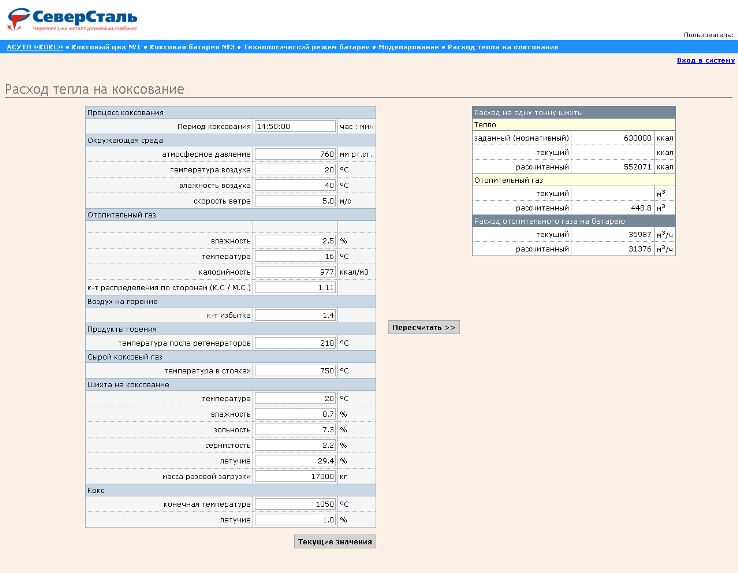

Calculation of heat demand for coking: