Coke oven hydraulic monitoring

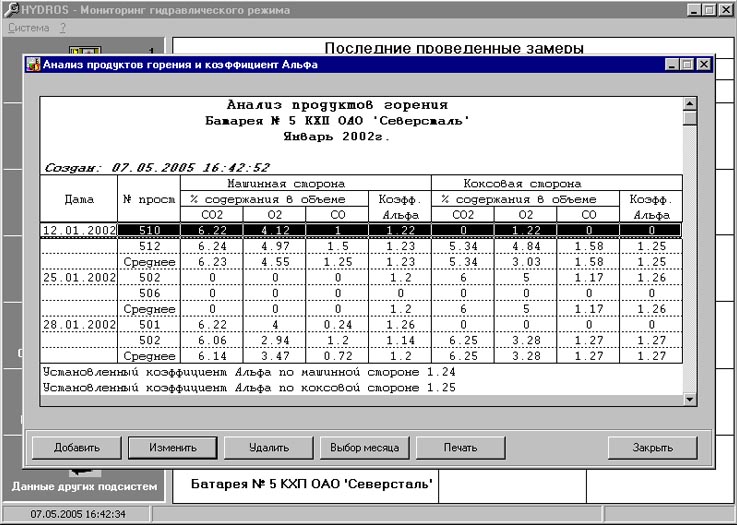

Coke battery hydraulic monitoring assumes control of heating gas burning with set air excess coefficient and combustion products flow with set pressures in control points. The main process parameters of hydraulic monitoring are pressures under the top of heating verticals and air excess coefficient controlled by rarefication in flues and air supply.

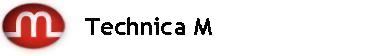

Pressure distribution

The following measurements are processed by the subsystem:

- pressure under the heating vertical's top;

- rarefication in raw gas pipe;

- rarefication under the top of heating regenerators on both sides;

- pressure in gas collector;

- openness of controlable inlets/outlets for air, gas and combustion products;