Reversing winch

Reversing winch provides periodic flow direction change for heating gas, air and combustion products in coke oven battery heating system. Usually, coke batteries are equiped with following types of reversing winches:

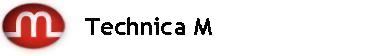

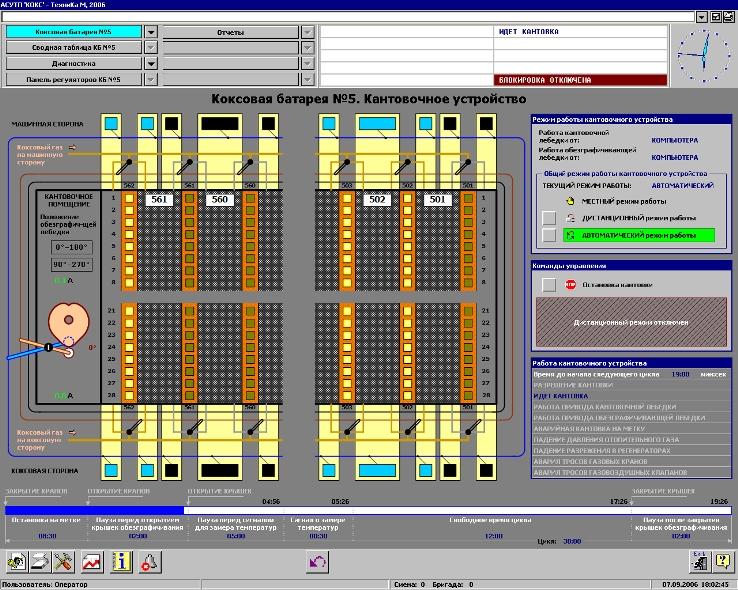

Proposed control system provides:- reversing winch work in automatic, remote and manual modes;

- automatic scheduling of reversing winch work cycles with ability to change duration of any phase;

- work cycle synchronization for reversing winches operating on different coke batteries;

- visualization and complete diagnostics for equipment state;

Electric reversing winch

Electric reversing winch moves ropes changing position of all gas and air valves simultaneously.