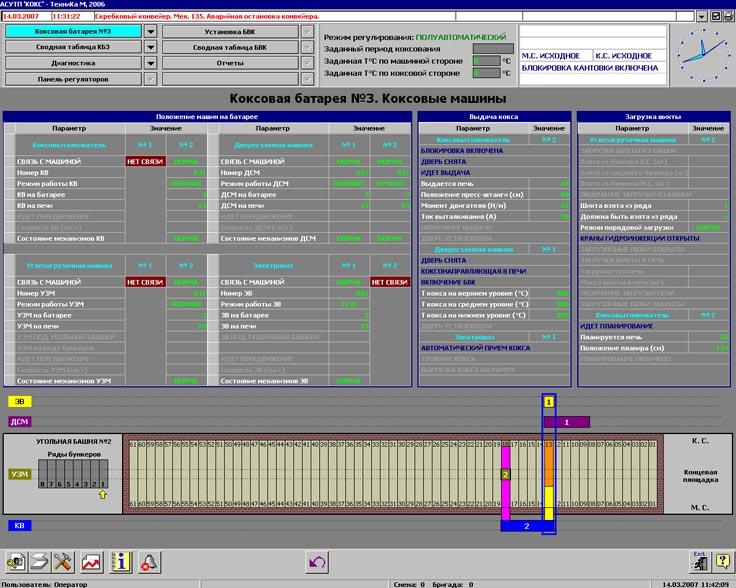

Coke machines

DescriptionUsually, coke oven battery is equiped with set of coke machines. Coke machine automation assumes the following main components:

- coke machine operation automation:

- travelling and positioning;

- process operation execution:

- charging

- pushing

- coke machines interlocks

- equipment and devices diagnostics.

- coke machine work supervising

- operator supervising;

- push/charge schedule execution;

- routine operation execution.

- process parameter measurements

Coke machine operation automation

Coke machines coordinated and correct work is guaranteed due to reliable communication channel between coke machines and higher level systems. We use wireless communication channels in our projects.

Coke machines receive oven number to move to from push/charge scheduling subsystem through wireless channel in real time mode.

Important part of any coke machine automation system is correct machine positioning on specified coke oven. Our experience of project's commissioning proves that we can guarantee positioning with accuracy of 5mm.

Вush/charge operations are fully automated.

Blend charging

Coke oven charging in automatic mode assumes control of loading devices with smooth change of blend charging speed to provide accuracy of loaded weight and uniformity of its loading. Synchronized work of pusher levelling ram and charger loading device ensures necessary distribution of charged blend in coke battery oven.

Coke pushing

Coke pushing in automatic mode provided with synchronized work of pusher, door guiding and quenching cars ensures control and execution of all coke machines interlocks. Pushed coke is received by quenching car in an automatic mode, moreover, to ensure its uniform distribution, quenching car movement is synchronized with pushing ram.

Coke pushing can result on coke dust emission to environment to prevent such a pollution the pusher sends command to dust-free coke pushing plant to switch on blowing devices to vacuum emitted dust.

Coke machines interlocks

Process safety during coke machines operation is especially necessary at coke pushing. To ensure correctness and safety coke machines use interlocks. Usually, information required for interlocks is transmitted through wireless channel.

Central part of interlocks is pusher car responsible for checking the position of envolved machines and granting permission to execute pushing operation.

In case of inadequate conditions the pushing operation is blocked, this is true even if operation is started, in such a case alarm operation abortion is taking place.

Coke machines operating and servicing is impossible without analysis of diagnostics information on hardware and equipment status. The system provides support for real-time and off-line processing of such diagnostic information, as well as its archiving.

Coke machine work supervising

Coke machines work could be supervised by battery operator and corresponding automation systems.

Operator supervision could take place either from local control room on the battery or from central control room in plant office.

Process parameter measurements

Push/charge operations are accompanied with measurements of process parameters required for higher level automation systems. Usually, the list of such measurements includes:

- charged blend weight;

- coke mass temperature profile;

- pushing ram current.