Ammonia extraction from coke oven gas

Descrition

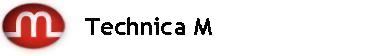

Coke oven gas purification from ammonia is carried out by a circular phosphatic method, using a way of ammonia absorption by absorbing solution of mono-ammonium phosphate in two-stage absorbers at a temperature of 40-50 °С.

As a result of ammonia extraction and its interaction with mono-ammonium phosphate, the contents diammonium phosphate containing resinous and other suspended impurities, washed up from gas, is increasing. In this case diammonium phosphate is exposed to a long settling in the special tar-stripping unit.

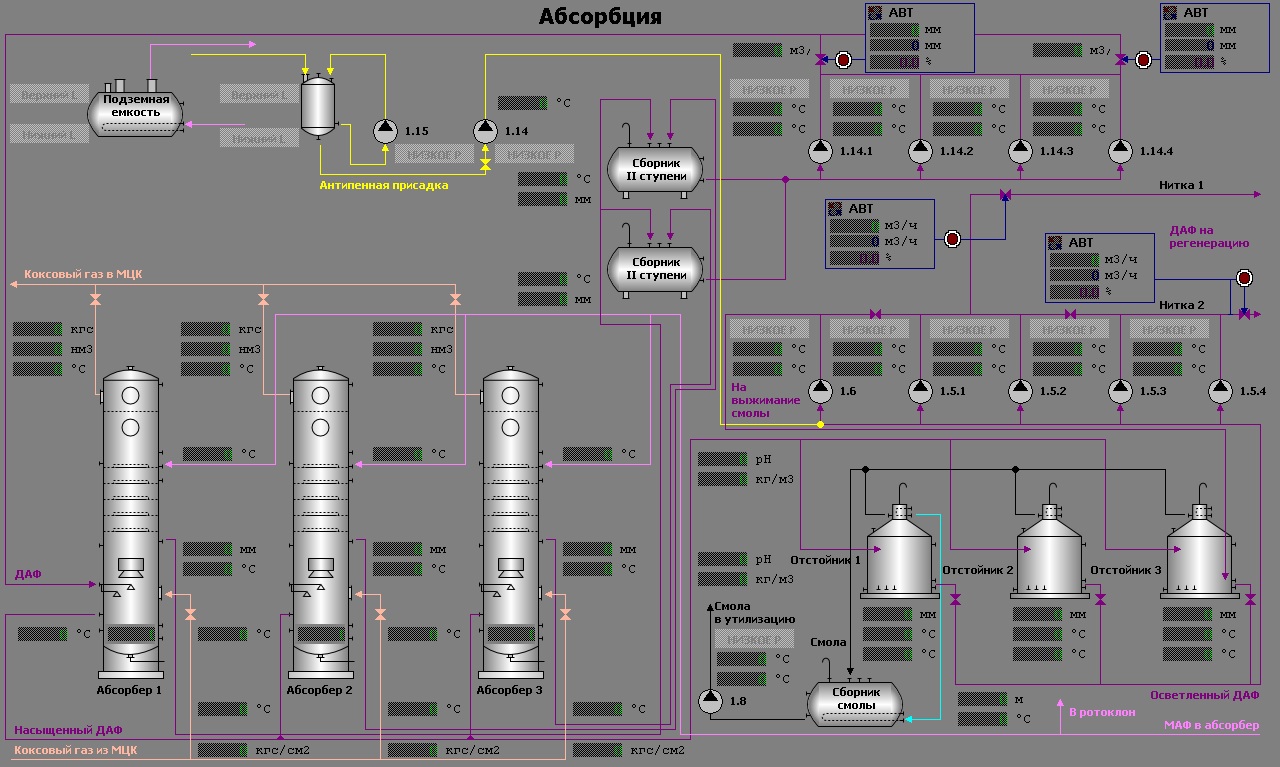

Then saturated ammonia solution moves to regenerators in which under the influence of temperature the diammonium phosphate hydrolysis with allocation of molecular ammonia is took place. Molecular ammonia is desorbing to a vapor phase and is carried away by a riser flow in the top part of a regenerator. The lean ammoniac water, together with mono-ammonium phosphate is removed in evoporator, where the partial vaporizing cooling of solution and an additional desorption of ammonia formed by water vapor are carried out. After an evoporator the regenerated mono-ammonium phosphate solution is finally cooled, and back moves in an absorber.

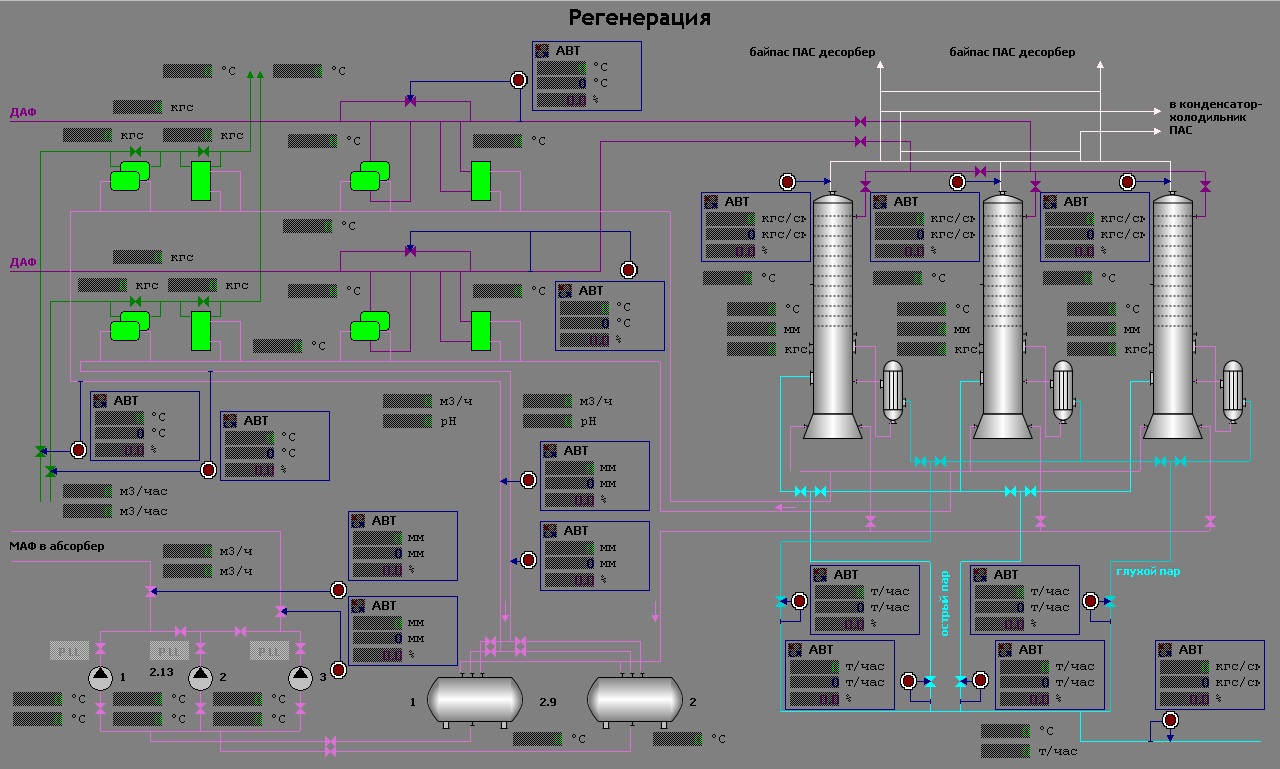

The formed ammonium-vapor mixture, for the purpose of ammonia destruction is exposed to burning in special combustors (reactors) under the corresponding temperature and hydrodynamic conditions.