Coke quenching

DescriptionAfter coke pushing into quenching car the coke is transported for quenching, where it is cooled to the temperature about 180-250°C. It is very important to guarantee constant humidity of cooled coke.

Proposed process control automation system provides:

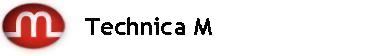

Wet coke quenching plant

Wet coke quenching assumes spraying over burning coke of water in special facility - quenching tower.

Proposed process control automation system improves:

- pump work control;

- auxiliary equipment work control;

- quenching cycle control.

Dry coke quenching plant

Description

Dry coke quenching assumes blowing of inert gas through the burning coke in closed system. Heated inert gas comes to boiler-utilizer where generates water steam.

Proposed process control automation system improves:

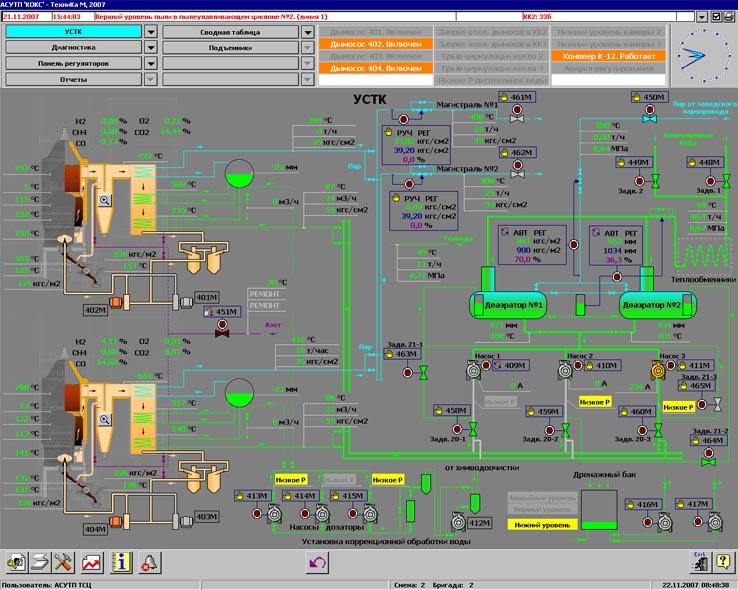

- quenching chamber process control;

- boiler-utilizer process control;

- quenching wagon lift control;

- coke loading-unloading facility control;

- auxiliary equipment control.

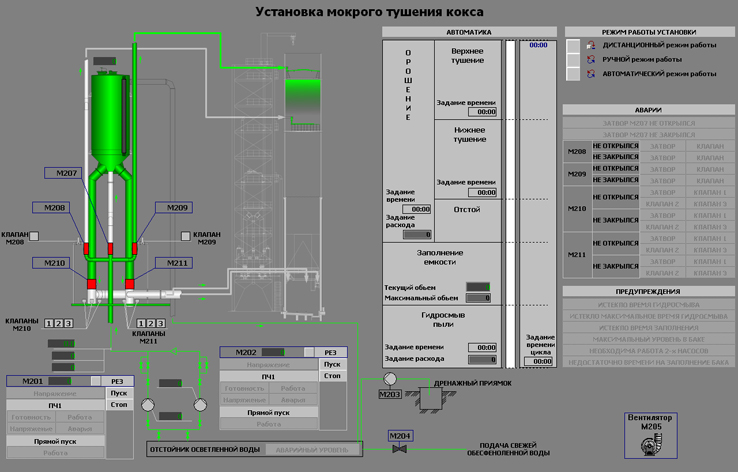

Coke quenching and steam generation cycle view provides control over main process

equipment and facilities (chamber, boiler, blowing device, etc.):

Coke quenching and steam generation cycle view provides control over main process

equipment and facilities (chamber, boiler, blowing device, etc.):

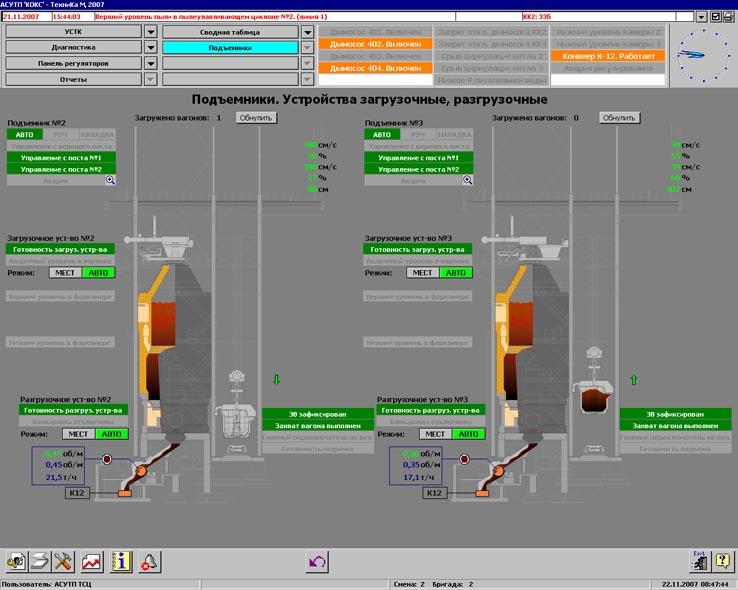

Quenching wagon lift and coke loading-unloading facility view provides control

over mechanisms of burning coke lifting, loading and unloading of cooled coke into

transport conveyer of coke screening facilities.

Quenching wagon lift and coke loading-unloading facility view provides control

over mechanisms of burning coke lifting, loading and unloading of cooled coke into

transport conveyer of coke screening facilities.